Success

Stories

With over 21 years of experience, GMO-Z.com RUNSYSTEM has continually affirmed its brand and reputation in the field of Information Technology by making its mark in building multi-domain technology systems for thousands of clients, creating intelligent products with high applicability that help increase work efficiency, and providing IT services such as hosting, domain names, cloud computing, etc., which are reputable and protected by leading global brands and partners.

Comprehensive ERP Solution for the Mechanical Engineering Industry

Mechanical manufacturing is considered a key industry in Vietnam’s economy.

SmaAD – Best Offshore Project of 2022

Determination: “No Ticket Will Be Delayed!”

The SmaAD project was implemented for GMO Tech in the advertising sector…

Cloud Computing Accelerates Retail Transformation

To continue growing robustly in this highly competitive industry, leaders must broaden their customer reach by managing multiple storefronts and supply chains,…

SmartKYC Integrated into Account Onboarding Process at Thien Viet Securities

Thien Viet Securities Joint Stock Company (TVS) is one of Vietnam’s leading investment banks, offering a full range of services to clients nationwide.

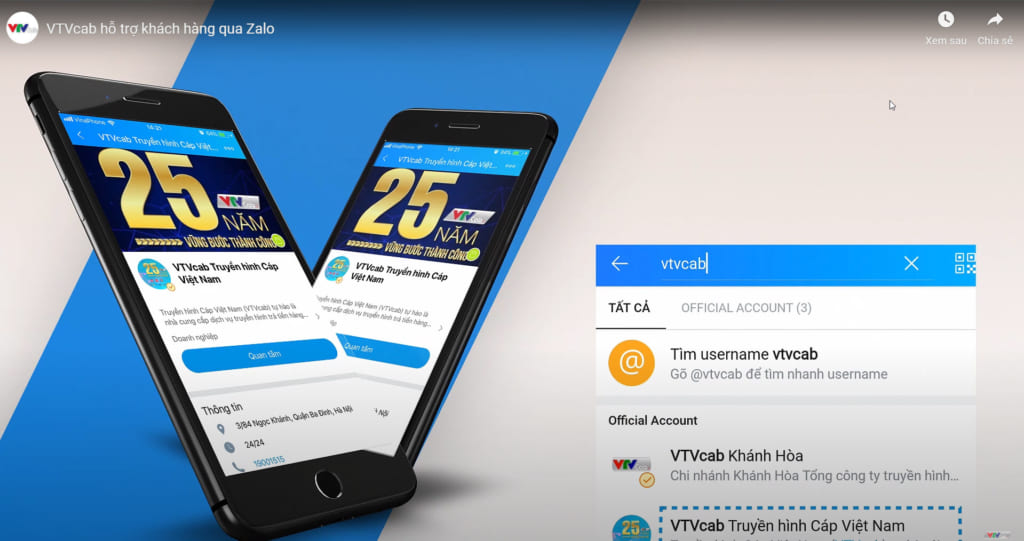

VTVcab Integrates SmartGift to Elevate Customer Experience

Vietnam Cable Television Corporation (VTVcab) (https://www.vtvcab.vn/), operating in the service industry under Vietnam Television (VTV), provides paid TV channels.