BaAN adapts to "post-COVID" thanks to the implementation of the Odoo ERP application by BizConnex.

Recently, BizConnex conducted a site visit and survey to assess the real-world performance after six months of successfully implementing and putting into operation the Odoo ERP management software for production operations at BaAn Joint Stock Company's Dong Van and Cu Chi factories. Following the impacts of the COVID pandemic, many Vietnamese enterprises have accelerated the adoption of technology in their business and production activities, particularly through ERP solutions. ERP is considered a fresh approach to comprehensive business management, especially aligned with the Industry 4.0 era. As one of Vietnam’s leading manufacturers of corrugated plastic pipes, BaAn has actively embraced IT advancements. In addition to investing in manufacturing machinery, BaAn also applies 4.0 software solutions to enhance work efficiency and optimize value delivery.

BizConnex successfully implemented the Odoo ERP project for BaAn's production operations

Surpassing many competitors, BizConnex successfully gained trust and became the strategic partner for BaAn’s key ERP project, which plays a critical role in the company’s digital transformation—changing many outdated and manual practices. Officially launched for live use in May–June 2020, the Odoo ERP system has proven to be a necessary step for BaAn’s production activities by solving many long-standing challenges. Previously, data from departments such as production planning, processes, maintenance, inventory, etc., were mostly stored in separate Excel files or manually on paper, making management and retrieval difficult. After the ERP system was deployed, all data, records, work orders, and production outcomes are now integrated into Odoo ERP. With just one click, all information is displayed comprehensively and visually, helping production staff and managers save significant time in operations and monitoring.

On-site survey at Dong Van factory

Regarding quality management, Odoo ERP serves as a digital library, storing all product quality assessment results, enabling users to easily monitor, search, and trace information anytime, anywhere. Especially for a manufacturing company like BaAn, labor safety is always a top priority. Through Odoo, the company can track the maintenance history of equipment and use this data to determine timely maintenance schedules, ensuring worker safety and proposing alternatives to prevent production downtime. Although it has only been in use for less than a year, the Odoo ERP system has significantly improved flexibility, reduced working hours, and cut costs—enhancing BaAn’s production processes to adapt to the current post-COVID landscape.

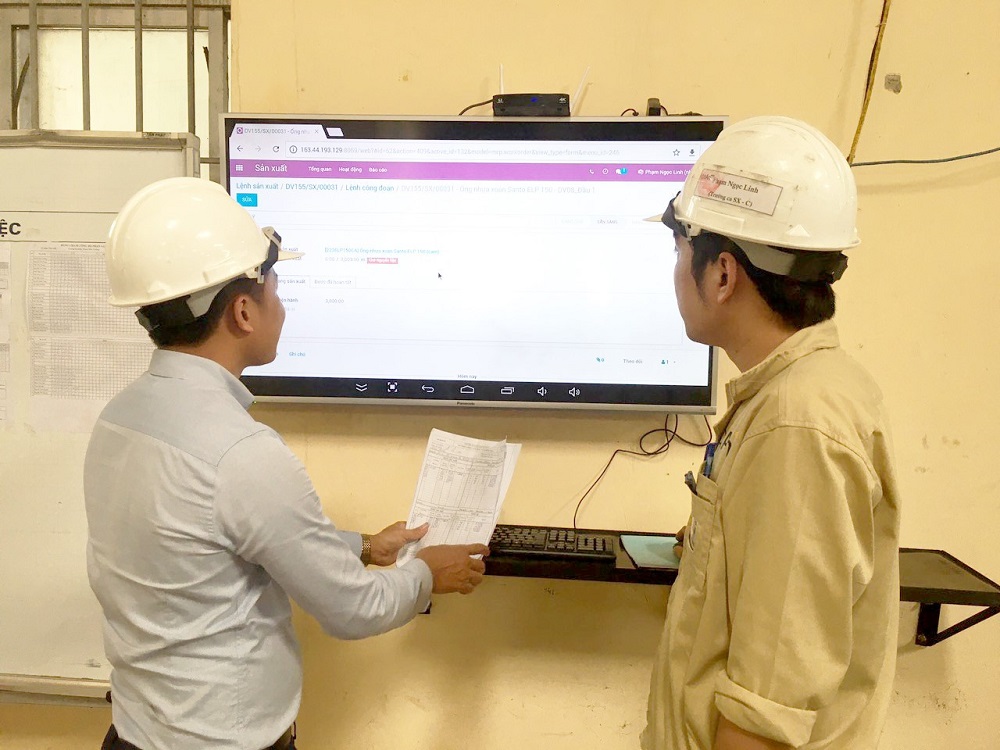

Factory staff switching from manual work to using the Odoo ERP system

“We are truly grateful to the BizConnex project team for their enthusiasm, professionalism, and timely, insightful advice throughout the process of building our system. In the time ahead, BaAn and BizConnex will continue to synchronize and complete the remaining modules to fully integrate them into our company’s operations,” shared Ms. Do Thi Xuan (Project Manager, representative of BaAn).