ERP System: A Powerful Tool Helping BaAN Adapt Post-COVID

Comprehensive ERP System Stands Strong Amidst the Pandemic

In response to the impact of the COVID-19 pandemic, many Vietnamese businesses have accelerated the application of technology in their operations, notably through ERP solutions. This is considered a fresh breeze in enterprise-wide management, especially under the Industry 4.0 trend. As one of Vietnam’s leading manufacturers of spiral plastic pipes, BaAn has also embraced the movement of IT application. Alongside investments in production machinery, BaAn has adopted 4.0 software solutions to enhance work efficiency and optimize value creation.

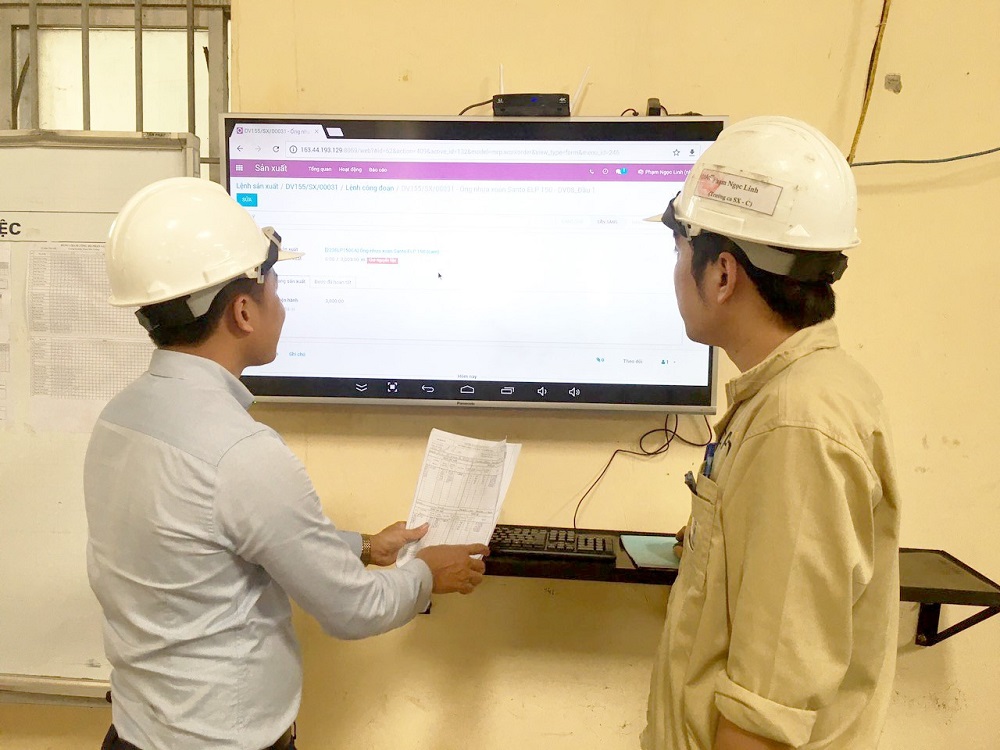

The implementation team successfully deployed the ERP Odoo project for BaAn’s manufacturing operations

Surpassing numerous competitors, the ERP Division earned BaAn’s trust to become the key partner in their digital transformation journey. This project significantly changed old habits and manual, fragmented processes. Officially launched in May–June 2020, the system was a necessary step in streamlining production, effectively solving several complex problems faced by BaAn. Previously, data from factory departments—such as production planning, processes, maintenance, and inventory—was stored in separate Excel files or on paper, making management and retrieval difficult. After deploying the ERP system, all data, records, orders, and production results are integrated into Odoo ERP. With a single click, all information is presented comprehensively and intuitively, helping both production staff and managers save considerable time in operations and monitoring.

On-site survey trip at Dong Van factory

In terms of quality management, Odoo ERP acts like a digital library, storing all product quality assessments and enabling users to monitor and trace information anytime, anywhere. Especially for manufacturing businesses like BaAn, occupational safety is a top priority. Through Odoo, the company can track equipment maintenance history and determine the right time for servicing, ensuring worker safety and providing backup solutions to avoid production downtime. Though the system has only been in real-world use for less than a year, ERP Odoo has already brought significant advancements—improving workflow flexibility, reducing costs, and helping BaAn adapt to the post-COVID era.

Factory staff shift from manual work to the ERP Odoo system

“We sincerely thank the project team for their enthusiasm, professionalism, and timely, insightful consultation throughout the system implementation. Moving forward, BaAn and GMO will continue synchronizing and completing modules for full integration into our business processes.” – Ms. Do Thi Xuan (Project Manager, BaAn representative) shared.

Project Results and ERP System Benefits

After implementation at BaAn, the ERP system streamlined operations from headquarters to factories and overseas branches. It addressed bottlenecks, reduced supply lead time, and met rising order demands. The system model and role-based access made sales operations more transparent.

Deployed Odoo Enterprise 12 with modules: CRM, Sales, MRP, QC, Inventory, Purchase, VAS

Customized access control for CRM and Salefie modules

Developed a Multi-Company model

Integrated barcode scanners